Hi there,

This is Allen from TECO. It’s great to know that you are interested in vitreous enamel panels. As a manufacturer of VE panels, I hope I can share with you some valuable information and experiences, which hopefully could help you move on your VE panel projects more successfully and carry your VE panels to your customers with better quality.

In the first post of this special series, I would like to tell you about how to improve panel flatness of vitreous enamel panels.

Panel warping is one of the most common issues that happens with VE panels. It won’t deteriorate panel durability, but it doesn’t look nice when all of the warping panels are put together no matter whether it is for interior or for exterior wall cladding.

The below picture is to show you what it looks like if warping issues have happened in your project:

And below is a picture that shows you the beauty of wall cladding when all panels go flat.

I can’t really stress enough how important panel flatness is. You know we’ve been in this industry for more than 20 years and I can’t tell you how many companies where we have had to come in and help them to improve their work because people have basically no idea how to minimize panel warping issues.

Therefore, I hope we can help you to prevent from this issue before you start your project. Here are the five things we think you should know before going for a vitreous enamel panel project.

- Panel Returns/Flanges

There are always varied sizes of panels in a project. Sometimes it may go less than ten sizes, but sometimes it could go above hundreds. In our experience, small panels have less warping issues, while it’s more common to see warping issues on big panels.

For better panel flatness purposes, if panel sizes go bigger than 1,200mmX2,400mm, then having bigger panel returns/flanges can help you achieve better panel flatness. Usually, a 30mm return/flange height is good enough for small panels, but a 40mm~50mm return/flange height is highly recommended if a panel goes beyond 1,200mmX2,400mm.

- Screw Fixing or Hook Fixing

In our experience, screw fixing systems always have more benefits than hook fixing systems. The best benefit of the screw fixing method is that it can achieve better panel flatness than the hook fixing method.

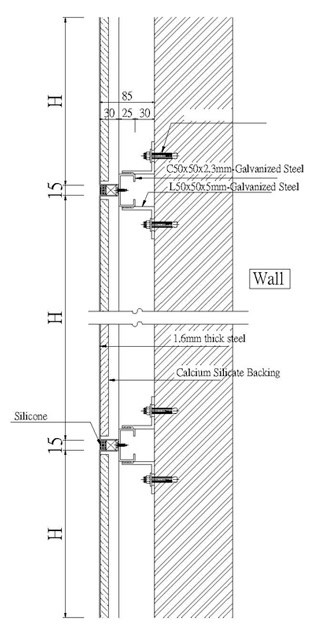

We can put screw fixing brackets on all sides of panels. However, hook fixing brackets can work only on vertical sides. The more fixing points, the better panel flatness that can be achieved. The ideal distance between each two screw fixing brackets is 300mm.

Please check out the drawings shown below for the design of screw fixing panel and the fixing system in sectional views.

More than that, screw fixing systems are easier for level adjustment than hook fixing systems. If any panels need to be dismounted for replacement, you can just unscrew the unwanted one without touching the others. However, in a hook fixing system, you always need to dismount topper panels first, while any button panels need to be replaced.

Are you still working on hook fixing systems? Why don’t you change to screw fixing systems? If you do so, I believe you will get better and easier jobs on site.

- Panel Shape

For better panel flatness purposes, pressing procedures are necessary after we bind backing materials onto the rear side of VE panels. The simpler the panel shape is, the easier pressing jobs can proceed and the better panel flatness will be.

Therefore, having simple panel shapes can always bring benefits on the panel flatness appearance. Let me take the below as an example for you.

Ex.

Pressing procedures cannot be continued on the two huge sides of U shaped panels. Panels like this design always have flatness issues. If a U shape design is a must, we suggest that the dimensions of the two sides are both less than a 300mm height so then the warping issue of the two sides can be minimized.

If you are designing non-typical panel shapes but wondering whether or not they will impair flatness, please feel free to call me anytime and I will be more than happy to discuss it with you further.

- Gloss Level and Surface

Before we talk about this topic, I would like to show you a picture here.

You can see from above picture that the image reflection from the low gloss panel is blurred, but the image reflection from the high gloss panel is clear.

Therefore, I recommend that the finish be of a type that will not reflect distinct images. If the reflecting power is high, images seen in the mounted panels will usually be distorted due to even very minor deviations from flatness.

Experience has shown that the overall appearance of a structure will be considerably improved if the image reflection (distinctness-of-image gloss) is kept as low as possible.

However, when vitreous enamels of especially low specular gloss are adopted, difficulties may be encountered in applying the acid resistance test.

You may ask – so what gloss level should we have on our wall cladding panels? Here are my suggestions for you.

As you don’t need to worry about acid resistance issues, for interior wall cladding application it’s better to have a low gloss finish to reduce image reflection in order to improve the overall flatness appearance of a structure.

However, for exterior wall cladding application, acid resistance quality is very crucial to the panel’s durability. Therefore, I suggest for you to adopt a high gloss and embossed finish in order to achieve the best acid resistance quality, as well as reduce the image reflection issue for better panel flatness appearance.

You may wonder what an embossed finish may look like and what its advantages are. Let’s take a look at the picture shown below.

You can see from the above picture that the image reflection from the embossed finish panel is blurred, but the image reflection from the smooth finished panel is clear.

Therefore, just like a low gloss finish, the embossed finish will not reflect distinct images so it can also considerably improve the overall flatness appearance of exterior wall cladding. More than that, with an embossed finish, we can still keep a high gloss finish which can retain the acid resistance quality of vitreous enamel panels.

The gloss and texture of the vitreous enamel finish, together with permissible tolerance in gloss, should conform visually with samples selected by the architect and/or purchaser during negotiation of the contract.

- Storage

We know how to store and protect our vitreous enamel panels well. However, sometimes when I go to project sites, I see many inappropriate ways the site workers are storing VE panels. It may not be their fault because they might not have any training or lessons about how to protect VE panels before they do the jobs.

Therefore, I hope I can provide some information for them here and I truly hope all site people can be well trained and pay more attention while they are handling VE panels so then unnecessary loss can be significantly reduced from sites. If you think the below information could be helpful to them, please do feel free to pass it to them.

HOW TO HANDLE VITREOUS ENAMEL PANELS ON SITES?

Appropriate storage can prevent VE panels from distortion. Uneven weight support when stacking up or laying down enamel panels on site could deteriorate panel flatness quality.

The below photos are showing you how the panels get distorted due to inappropriate storage.

If you have enjoyed this tutorial as much as I have enjoyed making it for you, and if you want to learn some more information and want to sign up for a free consultation, I can set aside some time for you! Click the link below to apply for your free consultation now.

CLICK HERE TO GET YOUR FREE CONSULTATION NOW!

If we think you are a good fit, we will be directly in touch with you. We look forward to hearing from you. Talk soon.

Allen.

Click the links below for more posts of this Insiders Report series.

PART 2 – Color Consistency PART 3 – Finished Appearance PART 4 – Maintenance