Beyond Initial Price: Understanding Vitreous Enamel Panel Life Cycle Cost for Infrastructure

Introduction: The Hidden Economics of Public Infrastructure

When planning major infrastructure projects like subways, tunnels, or airports, the focus often drifts to the initial material cost. However, experienced engineers know that the true cost of a building is measured over decades, not days.

Have you ever wondered why the walls of high-traffic metro stations in Singapore or road tunnels in Hong Kong remain pristine after years of abuse? The secret isn't an unlimited cleaning budget—it is the strategic choice of Vitreous Enamel (VE) panels.

In this article, we analyze the Vitreous Enamel Panel Life Cycle Cost to reveal why this 3,500-year-old technology is actually the most cost-effective solution for modern cities.

Forged in Fire: The Science of Longevity

To understand the value, you must first understand the material. Vitreous Enamel is not paint; it is a composite of glass and steel fused together at temperatures exceeding 800°C (1500°F).

This fusion creates a surface with "superpowers" that directly impact the bottom line:

Mohs Hardness 5: It resists scratches from luggage and vandalism.

Non-Porous Surface: It is impervious to chemicals and bacteria.

Inorganic Colors: The colors are locked in glass, meaning they never fade under UV light.

But how do these physical properties translate to financial savings?

Calculating the Vitreous Enamel Panel Life Cycle Cost

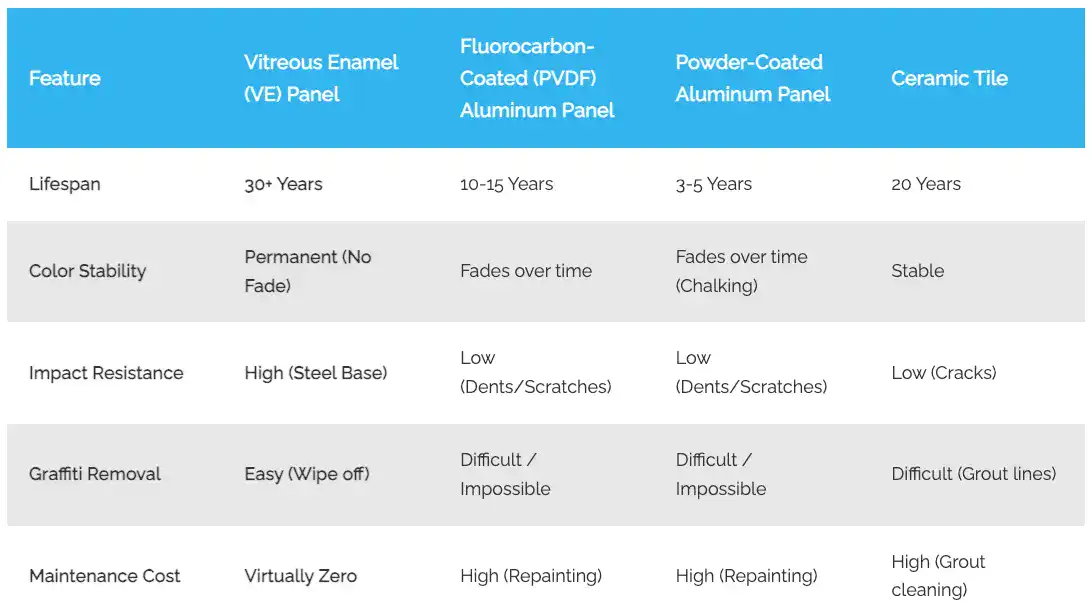

This is the most critical calculation for any project manager. While alternative materials like fluorocarbon-coated (PVDF) aluminum panels, powder-coated aluminum panels, or ceramic tiles may have a lower upfront cost, their maintenance requirements skyrocket over time.

When you factor in the cost of cleaning, repairing scratches, and the inevitable need for repainting every 10-15 years, the Vitreous Enamel Panel Life Cycle Cost proves to be significantly lower.

The "Install and Forget" Advantage: Because the surface is chemically inert and hard as rock, VE panels are virtually maintenance free. There is no repainting required—ever. Graffiti can be simply wiped away with solvents without damaging the finish, eliminating the need for expensive remediation crews.

Feature | Vitreous Enamel (VE) Panel | Fluorocarbon-Coated (PVDF) Aluminum Panel | Powder-Coated Aluminum Panel | Ceramic Tile |

|---|---|---|---|---|

Lifespan | 30+ Years | 10-15 Years | 3-5 Years | 20 Years |

Color Stability | Permanent (No Fade) | Fades over time | Fades over time (Chalking) | Stable |

Impact Resistance | High (Steel Base) | Low (Dents/Scratches) | Low (Dents/Scratches) | Low (Cracks) |

Graffiti Removal | Easy (Wipe off) | Difficult / Impossible | Difficult / Impossible | Difficult (Grout lines) |

Maintenance Cost | Virtually Zero | High (Repainting) | High (Repainting) | High (Grout cleaning) |

As the chart illustrates, while paint deteriorates and tiles can crack, Vitreous Enamel maintains its integrity for over 30 years. For busy transit networks with limited maintenance windows, the ability to avoid closures for wall refurbishment is a massive operational saving.

Real-World Proof: High-Traffic Durability

The economic argument is backed by global case studies. Major transit hubs across Asia and Australia utilize this material not just for aesthetics, but for its economic resilience.

- Hong Kong Tunnels: The Central-Wan Chai Bypass uses 76,000 square meters of VE panels. In this grueling environment of exhaust and soot, the panels remain easy to clean, ensuring brightness and safety without costly refurbishment.

- Taipei & Singapore Metros: These systems rely on the panels to withstand the daily friction of millions of commuters while staying visually brand new.

Conclusion: A Responsible Investment for the Future

Choosing construction materials is a choice between short-term savings and long-term value.

When you choose Vitreous Enamel, you are choosing a material that is fireproof, maintenance free, and built to last generations. By prioritizing the Vitreous Enamel Panel Life Cycle Cost, you are making a responsible financial decision for the future of your city's infrastructure.

Ready to optimize your project's long-term value? Contact TECO today to discuss how our solutions can fit your budget and timeline.